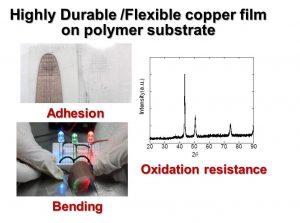

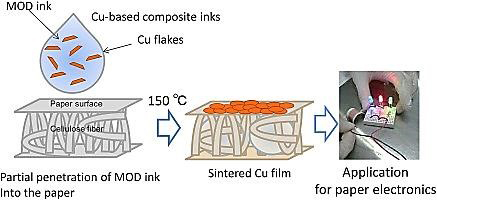

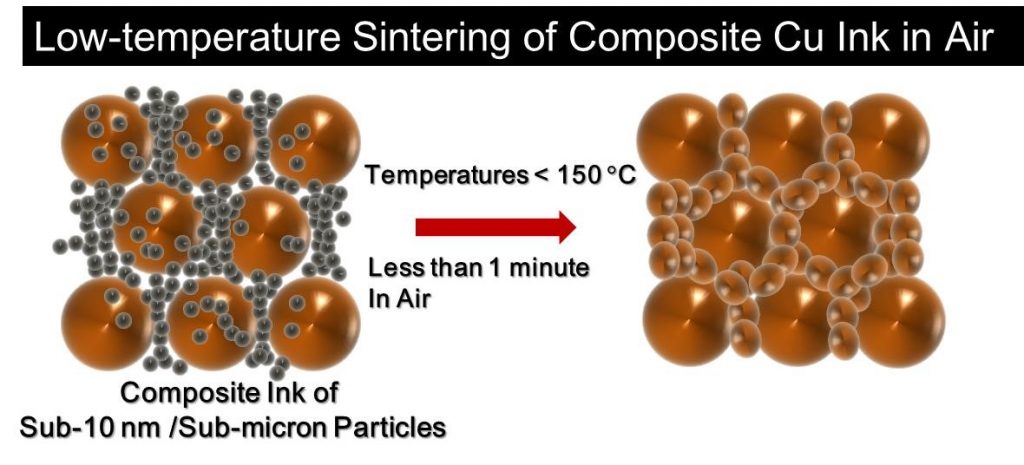

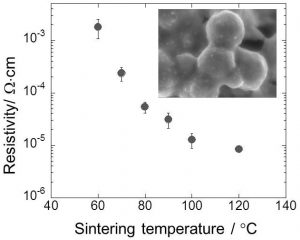

Most of the recent studies on conductive nanoinks have focused on silver nanoparticles because of their high conductivity and oxidation resistance. However, silver metals are too expensive to be used in large quantities. Furthermore, silver electrical circuits often suffer the problem of electro-migration. Therefore, Cu NPs are considered an alternative for conductive nanoinks because of their high conductivity, low cost, and reduced electro-migration effect. The major issue with Cu-based inks is easy oxidation in ambient air; the presence of copper oxide raises the sintering temperature and dramatically increases the electrical resistivity. To overcome these limitations, various types of copper-based inks have been developed to allow low-temperature (<150 °C) sintering for the preparation of conductive Cu films on flexible substrates: (i) reduction-assisted particle-based inks, (ii) nanoparticle-based inks with specific ligands, (iii) precursor-type inks (e.g., inks based on metal−organic decomposition, MOD), and (iv) combination inks. Our group focuses on low-temperature sintering of Cu-based inks to produce conductive Cu films on flexible polymer/paper substrates, ensuring the durability of sintered Cu films to safeguard their environmental stability and mechanical flexibility. These performances have become the most important task from a practical standpoint.

Most of the recent studies on conductive nanoinks have focused on silver nanoparticles because of their high conductivity and oxidation resistance. However, silver metals are too expensive to be used in large quantities. Furthermore, silver electrical circuits often suffer the problem of electro-migration. Therefore, Cu NPs are considered an alternative for conductive nanoinks because of their high conductivity, low cost, and reduced electro-migration effect. The major issue with Cu-based inks is easy oxidation in ambient air; the presence of copper oxide raises the sintering temperature and dramatically increases the electrical resistivity. To overcome these limitations, various types of copper-based inks have been developed to allow low-temperature (<150 °C) sintering for the preparation of conductive Cu films on flexible substrates: (i) reduction-assisted particle-based inks, (ii) nanoparticle-based inks with specific ligands, (iii) precursor-type inks (e.g., inks based on metal−organic decomposition, MOD), and (iv) combination inks. Our group focuses on low-temperature sintering of Cu-based inks to produce conductive Cu films on flexible polymer/paper substrates, ensuring the durability of sintered Cu films to safeguard their environmental stability and mechanical flexibility. These performances have become the most important task from a practical standpoint.

<Copper based conductive inks>

・Kawasaki et al. Chem. Commun., 47, 7740 (2011)

・Hokita et al. ACS Appl. Mater. Interfaces, 7, 19382(2015)

・Sugiyama et al. J. Mater. Sci.: Mater. Electron., 27, 7540(2016)

・Kawaguch et al. J. Coating Sci. Technol., 3, 56(2016)

・Kawaguch et al. Mater. Chem. Phys.,197, 87(2017)

・Akiyama et al. Adv. Eng. Mater. DOI: 10.1002/adem.201700259. (2017)

・Kanzaiki et al. ACS Appl. Mater. Interfaces, 9, 20852 (2017)

・Sakurai et al. Royal Society Open Science, 5, 172417 (2018)

・Sakurai et al. J. Mater. Sci. Mater. Electron, 30, 12130(2019)

・Kuroda et al. Colloid Interface Sci. Commun., 31, 100187(2019)

・Tomotoshi et al. Nanomaterials, 10, 1689 (2020)

・Tomotoshi et al. ACS Appl. Mater. Interfaces, 13, 20906(2021)

・ Sakaida et al. Mater. Lett.136238(2024)

・Ishikawa et al., ACS Appl. Electron. Mater., accepted (2025)

<Electroless copper plating>

・Nakasuji et al., Langmuir 41, 729 (2025).

<Silver based conductive inks>

・Keller et al. Mater. Lett., 284,128937(2021)

・Saita et al. Nanomaterials, 12, 2004(2022)

・Ikuto et al. J. Colloid. Interf. Sci. 679, 900(2025)

<Liquid metals>

・Manyuan et al. J. Colloid Interface Sci.649,581(2023)

・Otsuki et al. Mater. Chem. Phys.314, 128844(2024)