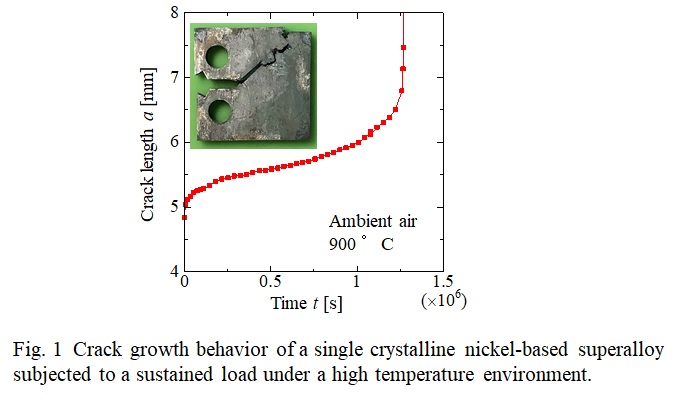

◆High-temperature fracture problem

The growing needs for energy efficient operation of modern gas turbines has boosted the use of sophisticated metallic materials (so-called superalloys) for blades attached to rotators. Since blades are subjected to an extremely high temperature environment, the evaluation of their life with a correct knowledge of crack growth mechanism has been an engineering issue.

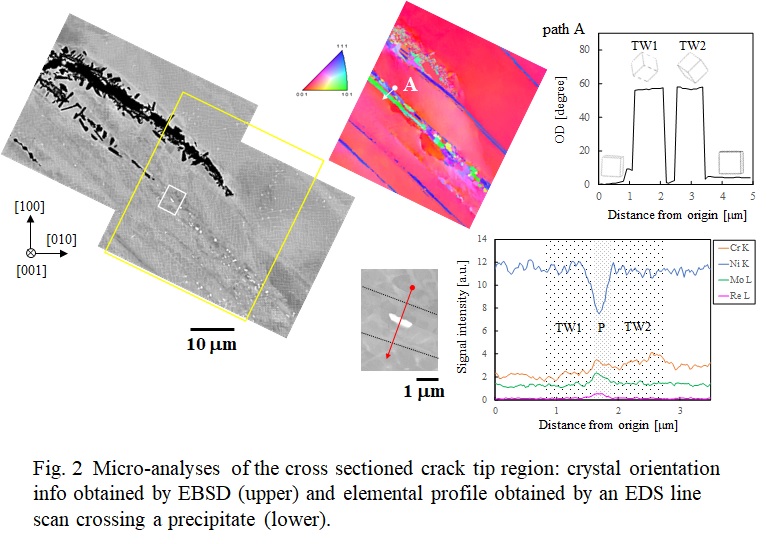

Our original site-specific observation technique successfully unveiled the microscopic features at the crack tip region in a single-crystalline nickel-based superalloy. It was found that the formation of twin bands triggered the precipitation of elements, resulting in degradation and cracking along the bands.

For more detail, see:

Y. Takahashi, D. Kobayashi, S. Fujii, M. Takuma, K. Saitoh, T. Sato, Time-dependent crack growth mechanism in Ni-based single crystal superalloys at high-temperature, Materials Science & Engineering A, Vol. 859, 2022, 144179 (https://doi.org/10.1016/j.msea.2022.144179)

Related study:

Y. Takahashi, D. Kobayashi, M. Kashihara, T. Kozawa, S. Arai, Electron-microscopic analyses on high-temperature fatigue crack growth mechanism in a Ni-based single crystal superalloy, Materials Science & Engineering A, Vol. 793, 2020, 139821 (https://doi.org/10.1016/j.msea.2020.139821)

Y. Takahashi, D. Kobayashi, S. Fujii, S. Arai, M. Takuma, K. Saitoh, T. Sato, Time-dependent subcritical crack growth and its mechanism in Ni-based single crystal superalloys at 500 °C, Materials Science & Engineering A, Vol. 889, 2024, 145869 (https://doi.org/10.1016/j.msea.2023.145869)